Silicone products for the diving industry

There is probably no more sensitive industry where quality must go hand in hand with reliability. That is why we are extremely proud to produce silicone components for the leading manufacturers of diving equipment. We have been trusted by companies such as Poseidon Diving Systems, Si-Tech and Interspiro. Our portfolio of products for the diving industry includes, among others:

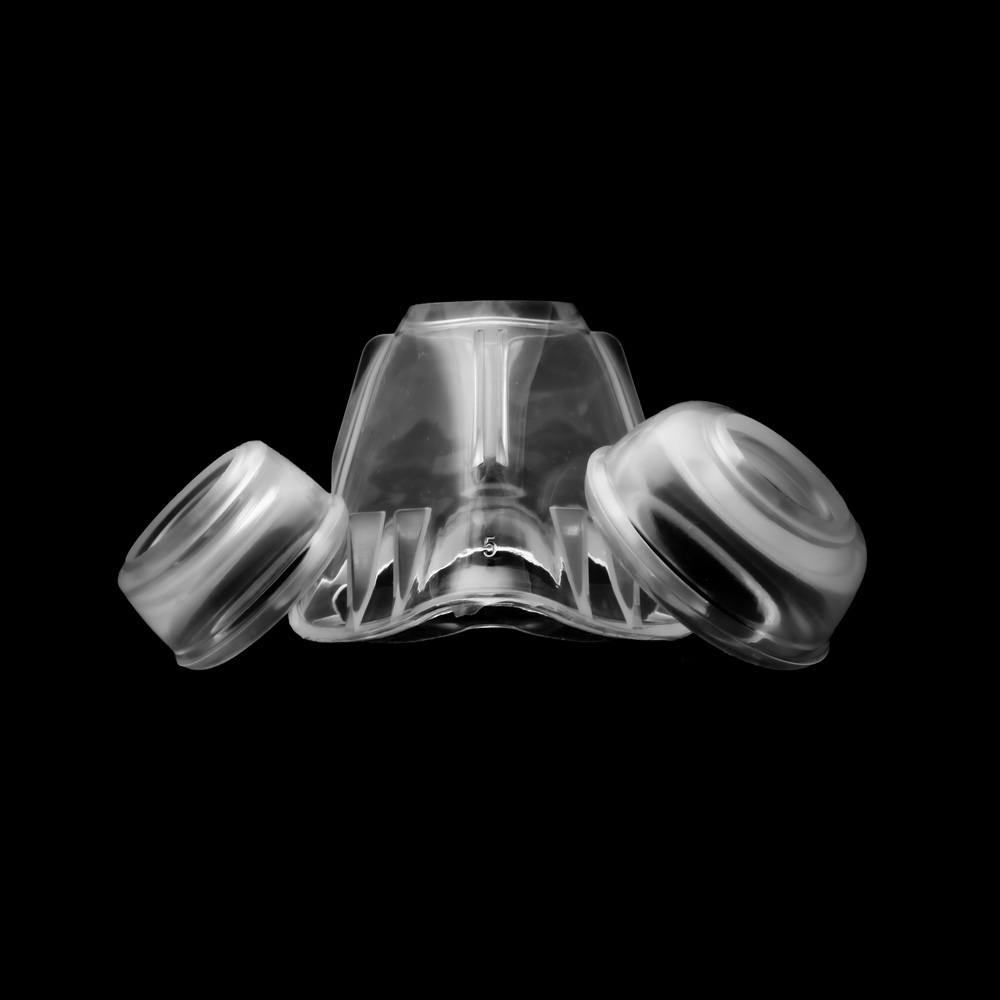

Wrist cuffs and neck flanges for dry suits

Latex orifices and cuffs are the cause of many problems as well as the diver’s uncertainty, and being underwater, it is impossible to wonder about the correct quality of operation of the equipment on which our life depends. The main problems latex cuffs face are that they are easy to cut and are sensitive to ultraviolet rays, chemicals and sweat. In addition, many divers suffer from latex allergies. Therefore, in response to the needs of our customers, we produce silicone seals and flanges with appropriate technical parameters, thanks to which they are free from the previously described defects. Silicone is hypoallergenic, 40% more stretchy than latex, more tear-resistant, and offers unparalleled comfort because it does not exert as much pressure on the body as latex, despite being stretched more strongly. Silicone does not require talc as it is „naturally” slippery. Silicone is resistant to ozone, chemicals, sweat and UV rays – it does not age. Additionally, what can be considered an advantage, silicone sleeves require the use of rings securing them to the suit. This allows their immediate replacement at the dive site with minimal technical skills and in just a few minutes.

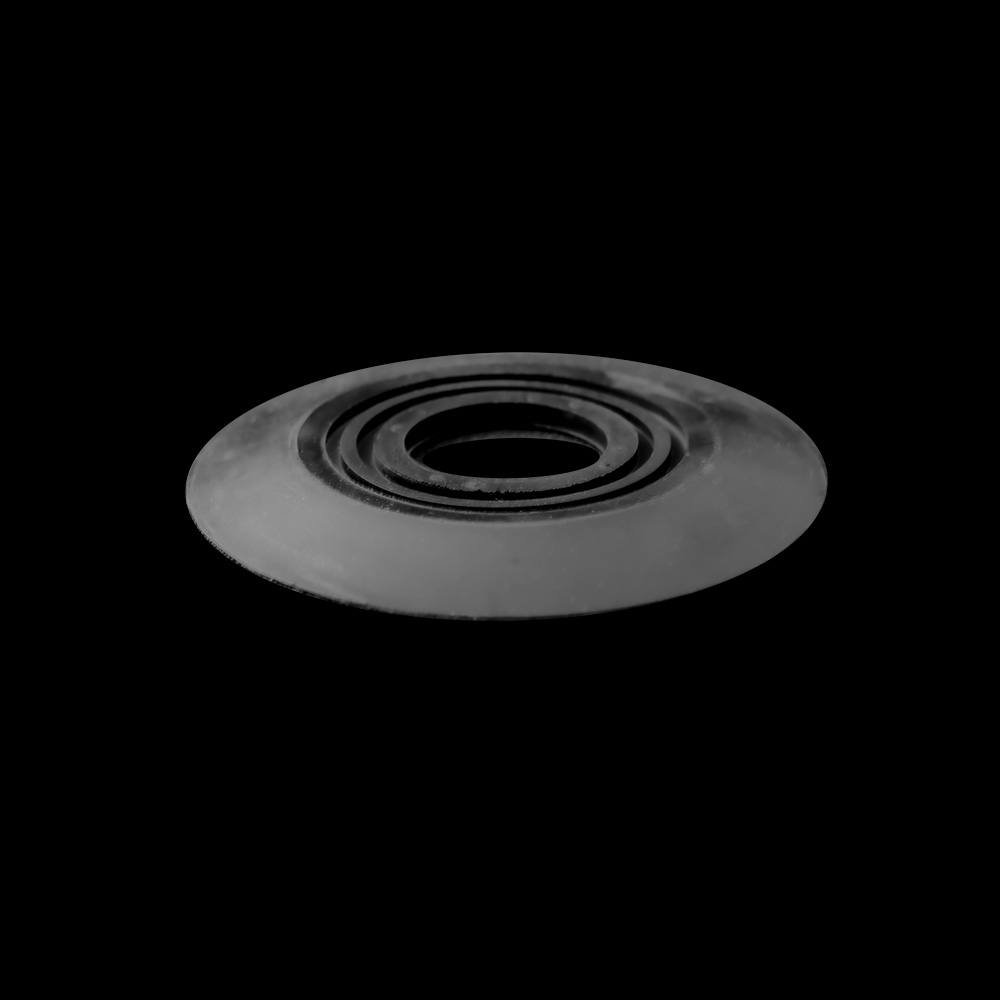

Relief valve ports

Critical places of dry diving suits, allowing the installation of bleed valves, ensuring watertight mounting of the valve to the dry suit. The silicone they are made of ensures a strong and durable connection, even in the event of a strong pull on the connection hose in an emergency. Additionally, silicone is resistant to unfavorable environmental conditions.

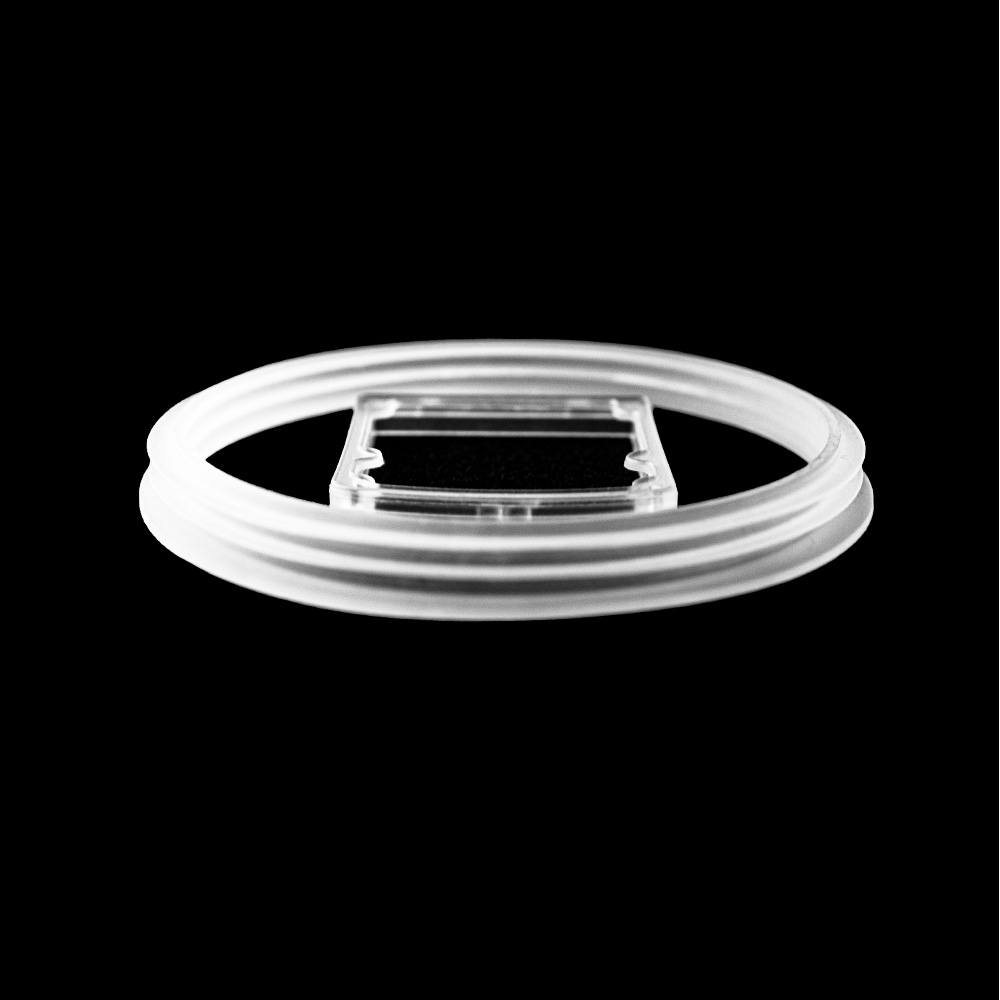

Diaphragms for valves

- Act as an automatic pressure relief valve

- Allow precise pressure changes inside the suit

- Must maintain a constant pressure inside the suit to control buoyancy