Silicone materials for the medical industry

We understand the importance of efficiency and processability when producing high-quality materials for the healthcare market. The excellent mechanical properties of medical-grade silicones make them ideal for the production of high-quality medical components and devices.

Medical grade silicones have long been used in healthcare, medicine and pharmacy due to their biocompatibility, chemical inertness, hypoallergenic, high physical performance and stability over a wide range of environmental conditions.

What is medical silicone?

Many companies use the term „medical silicone”. This usually means one of two things:

Medical long-term implantable material: This technical term describes a material that can remain in the human body as part of an implantable device. Due to its purity, it is generally too expensive for food applications.

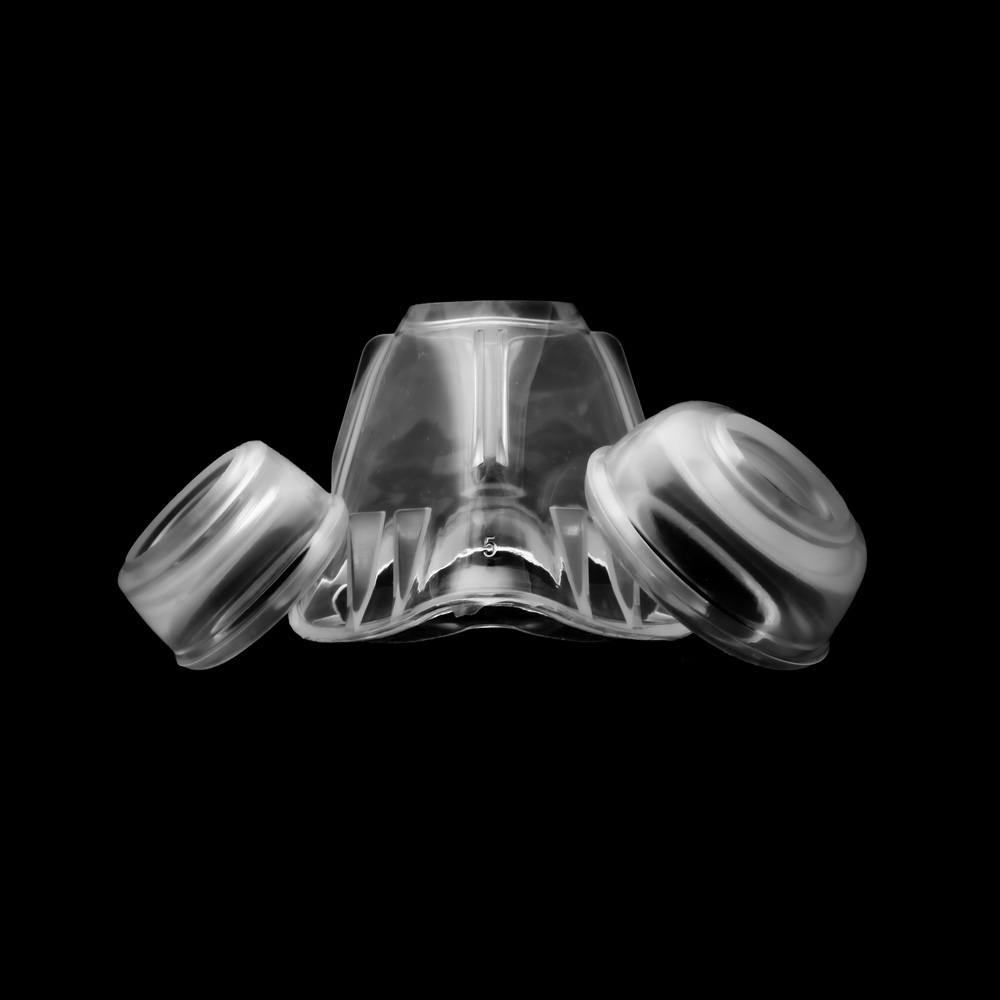

Medical Grade: More technically referred to as medical-medical grade, biocompatibility tested grade VI silicone, this type is our material of choice for a wide variety of products including menstrual cups, all kinds of medical components and skin contact products.

Both medical-health class VI and implantable for a long time are considered safe in contact with food. Both grades are almost always referred to as Liquid Silicone Rubber (LSR), which is injection molded to produce clean, consistent parts.

As in other industries, manufacturers of medical devices are always looking to reduce costs, improve the quality of their products and extend the service life.

The focus on long-term cost and price stability has a direct effect on sales revenues and producers’ profits.

The medical devices market requires a lot of skills and research, especially in the field of material selection and production processes.

In the medical industry, material performance can make the difference between health and injury. Consequently, whether you are evaluating metal, plastic, ceramics or liquid silicone rubber (LSR) for your medical device, the most important aspect to consider is the compatibility of the material with the functionality required by the equipment.

When selecting materials for new medical equipment and devices, engineers must consider a number of factors such as biocompatibility, qualifications, regulations and costs.

In the case of silicone medical devices, many applications include components that can withstand a variety of harsh conditions, such as heat, high pressure, chemical exposure, and biocompatibility.

Until the advent of the LDS, medical device manufacturers had difficulty finding materials that met their criteria for custom silicone molded parts and assemblies.

Medical grade silicone molding is suitable for dental and surgical applications, consumer health products and other medical products and devices.

Sterilized products

When it comes to sterilization, materials such as thermoplastic rubber or other rubber gaskets fail and age under extreme temperatures and chemicals. However, liquid silicone rubber has long-lasting, non-aging mechanical properties with minimal deviation in extreme temperatures and situations. Each LSR product can be treated with ethylene oxide, steam autoclave, electron beam radiation and gamma radiation without damaging the silicone rubber.

Vibration dampers

We can also develop precision equipment such as vibration dampers. If you are using advanced electronic or mechanical equipment such as surgical cutting tools, strategically positioning a vibration damper on the device can reduce vibration, ensuring greater accuracy during surgery or other skilled practices.

Seals and O-rings

LSR is an ideal material for the production of silicone rubber gaskets, seals and O-rings due to its high purity and chemical inertness. Our rubber solution can keep low mechanical aging, compression deformation and stress relaxation. LSR outperforms other rubbers when it comes to valves, seals and electronics housing.